Commutamatic II

Maxion

development log, part four

in which the chassis is improved and the drive is refined.

last updated 08/18/1999

Your comments are always welcome. Send me email!

The story resumes now, after a total cost of $1153 and total time of 163 hours and a reasonably successful test drive.

July 21 and 22, 1999. After learning from the test drive, I am back to work on it.

- More nuts, bolts, T-nuts, and pre-drilled steel. $25.

- Disassemble electronics and remove them to safety.

- To prevent sagging of the cross members: Add reinforcement to upper rear cross piece.

- Plan the addition of four more struts (to the existing four) to beef up the rear end.

- Fabricate lower shock mounts, weld in place.

- Fabricate upper shock mounts.

Total cost so far: $1178. Total time so far: 185 hours.

The two Commutamatics meet just before Commutamatic I is scrapped. (Click any for an enlargement.)

Top left: Commutamatic II, the Maxion, tilting 45 degrees, is on the left; Commutamatic I is on the right.

Top right: Commutamatic II, the Maxion, in the foreground; Commutamatic I is the farther.

Bottom: Commutamatic I is on the left; Commutamatic II, the Maxion, is on the right.I learned a lot on the first one.

July 23 and 24, 1999. The improvements driven by the lessons of the test drive mostly implemented.

- Weld upper shock mounts to frame ends. Now, four struts per rear wheel. Beefy.

- To prevent sagging of the cross members: Weld on a second piece of steel to the bottom frame's rear cross member.

- To prevent the side-to-side flexing of the driver's section: Add diagonal braces from besdie the driver's legs back to the rear.

- To further prevent side-to-side flexing of the battery section: Add diagonal braces from the bottom frame's rear cross member back to a pivot point inder the middle of the battery deck.

- Begin rebuilding the battery box; use 3/4" plywood on front and back instead of 3/8".

Total cost so far: $1178. Total time so far: 203 hours.

Note backward leaning black-and-white strut. It's one of four added to beef up the suspension. With the Trojan T-145s removed and replaced with lighter 12v RV batteries, this will be just the right amount of support.

July 25 to 28, 1999. Light duty work on the thing.

- Temporarily hang speedometer on front fork... how fast have I been going, anyway?

- Buy a few more T-nuts, etc. $10.

- Finish rebuilding main battery box.

- Reinstall batteries.

- Assemble better power cables, attach them.

- Create forward battery platform for the 12v auxilliary battery. (The aux. batt. will power lights, horn, relays, etc.)

- Attach low beams and horn.

- Cut pieces for permanent tilt-lock. (They'll bolt in place. One thing at a time: no tilting until I get my drive system figured out.)

- Test drives! Motors in parallel and in series.

Total cost so far: $1188. Total time so far: 226 hours.

This excerpted from an email I wrote:

I have recognized that I have two problems to contend with first, one tractable, one more difficult. The tractable one is that I am experiencing voltage drops in my system apart from the motors. Part of it is in some dirty connections and some undersized wires; I am dropping as much as 3 volts (!) circuit wide and heating up some connections and short spans. (That's about a kW all by itself!) Shame on me. The other part is that my six 6v batteries, which were freebies from a guy refreshing the traction pack in his converted Chevy S-10 (96 volt machine... a real beaut!) may not have enough life in them, even for me. I get pretty big sag on demand (the nominal 36 will drop as low as 30.5, which is a little below the magic cut-off I have been told about of 1.75v per cell, or 31.5 for the pack).

Between those two voltage loss things, I am getting only about 28v across my TWO motors under load, obviously that's a big step off of the 36v I could have. Old batteries do get some pizzaz back with a few cycles of use, but I may have to bite the bullet. Load testing per battery, and a hydrometer, are in my immediate future. But then, maybe these aren't the right batteries... which brings me to the larger problem.

The tougher problem goes back to my misreading the load label on my donor bikes' back fenders. Really, the 500 lbs of batteries is a lot for my frames, even having added two shocks/springs to the original pair on each of my donor motorcycles' rear ends. My first order response, I think, will be to go to smaller batteries and sacrifice range for now. I have 4 12v deep so-called "deep cycle" marine/RV batteries to play with, and to experiement with.My thanks to my father-in-law and to Bob Batson of Electric Vehicles of America for their very useful consultations on my observations.

July 29, 1999. More thinking.

- Buy three more deep-cycle batteries. I have 72v worth of batteries now, even separate from the 12v auxilliary battery. $240.

Total cost so far: $1428. Total time so far: 227 hours.

More thinkin'...

- I will cant the rear wheels out a little; they tend to lean in (bow-legged from the back). Even though I will have a little drag (camber thrust!) and some wear, it'll be tougher and better on my spoked wheels.

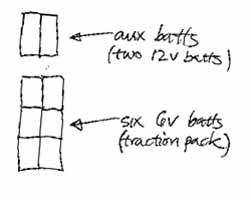

- I will swap out the six 6v batteries and put in five 12v batteries instead. This way, I lighten my battery burden some, and increase my voltage by a factor of two. The cost is in range. (In an EV, pounds of lead is like gallons of gas in an ICE.) The lightening is not just in the reduction of the numbers of batteries, but also in the fact that each of these batteries is lighter by about 10 pounds.

Current battery configuration, left. New configuration, right.

July 30 to August 2, 1999. A little work and a little time away.

- Install forward 12v batteries.

- Wire up system at 48v. (The new 12v batts are waiting for a little more understanding.)

- Take voltage readings, under load, of system with one motor and two motors wired in series.

- Take Westinghouse motor apart, clean connections.

- Have lovely wife drive at 20 and 25 mph down the street ahead of me to verify speedo. Checks out ok, crude thought the test is.

- Order two shunts and 400A meter from Bob Batson at Electric Vehicles of America. $140.

Observations:

- Either motor alone, or the two motors in parallel, or the two motors in series all give a max speed of about 22-24 mph.

- Either motor, when wired up alone, gets damn hot.

- Either motor, when wired up alone, only gets, at most, 27v across it.

- The output to either motor wired up alone is only 27v at the controller.

- The output of the controller when the two motors are wired in series is the same as the input to the controller: 44v.

- The controller stays much cooler in series mode.

- Note much better torque when the two motors are wired in series.

Total cost so far: $1568. Total time so far: 233 hours.

It'll be a good diagnostic tool to have current measurement, that's for sure.

Being watched like a hawk. This marsh hawk, or northern harrier, is one of three who tears apart rodents for lunch around our house. They seem to like the radio and the grinding wheel ok, or at least they are not repelled.

- Replace high-tech, solid-state controller with a big, fat, old resistive controller from a golf cart.

- Test drive: oops! Too much current too fast: bend chain tensioner. Reminds me afresh to respect hundreds of amps.

- Connect other motor instead. Try again.

Observations:

- Measure 38v across motor, and STILL get only 22 mph (and a lot of heat).

Conclusions:

- I am, to use Bob Batson's phrase, "motor limited." The suggestion is that the motor can deliver the torque I want, but not at the speed I need given the gear ratio to the rear wheel.

- Further, this suggests that the controller "knows" not too deliver more voltage than the motor will efficiently use; that's why it only gives the controller 27 volts at most.

- The next test will be to replace the jackshaft sprockets, currently both 16 teeth a gear reduction of 3 (12:16 then 16:36), with new ones, 12 teeth and 24 teeth, for a gear reduction of 1.5 (1:1 and 24:36). This should make the (apparent) top end 1000 rpm input deliver 48 mph at the rear wheel. (Ideally, I would choose a lower top speed, but my sprocket pusher only had a 24 toother for the 5/8" chain pitch and 3/4" shaft.)

- The big question is whether the motor can deliver enough torque at this lower ratio, or whether I am just trying to get more out of a lil' golf cart motor than is possible. We'll see...

Total cost so far: $1568. Total time so far: 235 hours.

Big, fat, old resistive controller from a golf cart. This controller is about 20 years old, but is reliable for its simplicity. It is basically a giant variable resistor with a wiper that contacts the resistive element at different points along its length. The longer the path through the resistor, the higher the net resistance. The last point of contact bypasses the resistor altogether.

- Order two new sprockets from Olmstead Flint (my drive components source in Medford). No cost; trade them with a pair I bought that were the wrong pitch. UPS should bring them on Monday.

- Replace big, fat, old resistive controller from a golf cart with the original high-tech, solid-state controller.

- Swap out the six Trojan T-145 batteries with four deep cycle marine/RV batteries from Sears. Sheds 450 lbs, adds about 240 lbs. Net lightening of 210 pounds, and it shows.

- Wire up the two remaining marine/RV batteries and the four new ones in pairs: 36v pole to pole from the six of them.

- Install the two shunts. These precise, temperature stable, low resistance elements have 50mV across them when 400A are going through them (!). These are for current measurement to each motor; the meter will be mounted on the instrument panel with a toggle switch to select which of the motors to measure.

- Weld up rods and mounts for locking the frame without tilt, and bolt them in place. No tilting until propulsion is debugged.

- Repair bent chain tension rod on right motor. (Damaged during 48v test; see preceding entry.)

- Wire up motors in series.

- Visit Sears, and purchase a new garbage disposal, and replace the one that hasn't worked since we moved in. (No, it has nothing to do with the Maxion, but it was part of a lost day!) Buy new work boots, too.

- Test!

Observations:

- Measure 280A and 34v for a rabbit start. Brisk feeling, but at the controller's limit.

- Measure about 100A at about 34.5v for cruising at 22 mph on flat ground. (3500W, or about 4.6 hp. Seems high. Oof. But runs cool.)

- Discover one not cool place: a feeble crimp! Redo, and it stays cool, too.

- Oops! Throw a chain.. Rewire to use just left motor. Measure a horrible 275A at 27v (7500 W, or about 10 hp, to get rolling. No wonder it gets hot.)

- Fix chain.

Conclusions:

- Can't wait to try the new sprockets.

- Even a volt drop across a bad crimp is horribly wasteful: at 275A, that's 275W wasted as heat. Wasted, Jerry!

Total cost so far: $1568. Total time so far: 245 hours.

- Receive the new sprockets. Thanks, UPS guy! Install them.

- Test. It won't go at all. It. Simply. Won't. Go.

- (It turns out to be the controller, but the test is a failure anyway... read on.)

- Drive to Medford and swap the 1.5:1 sprockets for new ones, working toward a 6:1 ratio. $40.

- Install sprockets for a 4:1 ratio, and the big fat old resistive controller from a golf cart.

Observations:

- The controller will only deliver 80A, not 275A, no matter what I do. Tech support for Curtis says to send it in. Bwah.

- The test of the low ratio is a flop. It turns out that not only was my father-in-law right that I needed a higher, not lower, ratio, but also that I had misunderstood Bob at EVoA who was saying the same thing. In retrospect, I was a little too willing to deny my own intuition. Hindsight, hey.

- After installing a new sprocket to surpass the orginal 3:1 and achieve 4:1, I succeeded in driving over 30 mph and was still accelerating when I ran out of cul-de-sac. The motor never even got hot. That's a new speed record, and validation of the higher ratio hypethesis. I don't know what the current was; I was watching the road like a good little driver. More on that later.

Total cost so far: $1608. Total time so far: 252 hours.

August 11-13, 1999. Looking forward to inspection.

- Have in hand sprockets to make 6:1, but I am sticking at 4:1 for more complete testing.

- Buy lighting components, flasher element, crimp lugs at ADAP. $25.

- Buy automotive relays at Radio Shack. $12.

- Try to decide how to shape roll cage. It's too much, though, because it defines the shape of the body to a large extent. Put it off.

- Fabricate and weld on light frame for dashboard.

- Fabricate and weld instrument supports. This will give the trio of speedo, voltmeter, and ammeter front and center. Support will also serve to attach front brake cable link.

- Add locking nuts to chain tensioners, as they keep getting loose.

- Try wiring up the two motors in parallel with big, fat, old resistive controller. Test.

Observations:

- Cruise at 32 mph and approximately 150A. That's about (150A)(36v) or 5400W or about 7 hp. Not too efficient.

Total cost so far: $1645. Total time so far: 264 hours.

The instrument cluster. Top left: 20-year-old Curtis battery gauge. Bottom left: the speedometer/odometer/trip odometer from the donor Honda bike. Center: Radio Shack digital multimeter - with a switch on the dash, allows the driver to check the voltage across either motor, the entire battery pack, any battery pair, and the controller output. Top right: ammeter - with another switch on the dash, allows the driver to check the current through either motor. What else could you want to know? Grin.

August 14-19, 1999. Strippin' and crimpin', crimpin' and strippin', and the days run like water.

- Buy a few more switches, wire at Radio Shack. $20.

- Wire up headlights

- Wire up directionals

- Wire up brake lights (including a third light, hust like the newfangled cars got)

- Wire up horn

- Wire up main contactor enable

- Wire up voltage sensing circuit for entire battery pack through selector switch (DP6T rotary) on dash

- Wire up antique Curtis battery gauge

- Wire up running lights

- Wire up brake light switches, lights

- Wire up current sensing circuit for each rear motor through selector on dash (center off, DPDT)

- Repair front hub stop (popped out during hard brake test. oooh.)

- Weld up stiffener for left jackshaft support

- Wire system for

Observations:

- Who knew all this would take so damn long?

Total cost so far: $1665. Total time so far: 290 hours.

Back to Back to Max Hall's homepage.